2.3.3Turnkey

Management approach

SBM Offshore continues to actively engage with clients, to transform its product offering by optimizing and standardizing its designs and leveraging its leading technology expertise in offshore mooring systems, in order to better fit the constraints of a CAPEX-limited climate. This year saw the Company‘s order intake increase compared to 2016, reflecting the year-end award for a turnkey turret. Overall though, the industry environment continues to be challenging and as such, project activity requiring such products is slow.

SBM Offshore’s Positioning

FPSO Market

SBM Offshore is a leader in the FPSO market both in terms of scale economies and track record, on key indicators for cost, schedule and risk reduction and actual throughput. To keep this leading position, the Company continues to invest in new technology, offering cost-optimized solutions across the full lifecycle:

- Technology development programs − the two main ones are: reducing delivery time via standardization (Fast4WardTM) and improving efficiencies and productivity through digitalization (digital FPSO),

- Leveraging the Company’s experience and business model by strengthening its position in its core markets, Africa and Brazil, while looking to develop sustainable business in new regions.

Gas

Although the market for floating liquefied natural gas (FLNG) solutions (new build to date) has yet to come to maturity, the following segments could be identified based on production capacity:

- Large structures of >3 million tonnes per annum (mtpa) of natural gas production

- Mid-size systems ranging between 1 and 3 million mtpa (SBM Offshore’s target)

- Smaller solutions of < 1 mtpa

The market for conversions has yet to develop. SBM Offshore is targeting both newbuild and conversion projects with its complete portfolio. At this moment the Company’s experience consists of the execution of a floating LPG solution and numerous floating LNG (pre)feed studies. Additionally, and similar to the FPSO market, SBM Offshore has built a strong track record in turret mooring solutions for floating gas systems.

Renewable energy

SBM Offshore focuses on two markets for floating renewable energy production:

- Floating Offshore Wind (FOW)

- Wave Energy

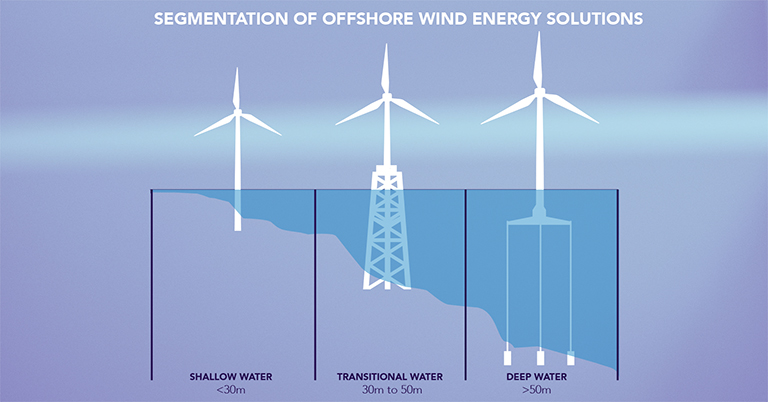

FOW segmentation is mainly determined by field characteristics, i.e. wind speeds and water depth. Different types of solutions are available in the market - semi-submersible, SPAR and TLP designs, the latter being the focus for SBM Offshore, by leveraging its experience in past TLP projects and deep water mooring systems.

For Wave Energy the market is currently developing with no real segmentation; options can be differentiated by the generation of technology used. The industry has seen pioneering projects and pilots enjoy little success due to high OPEX and therefore high Levelized Cost of Energy. SBM Offshore’s solution passes such limitations with a design with no mechanical components.

2017 Performance

- From a delivery perspective, two complex turret mooring systems were commissioned and delivered for the Ichthys and Prelude projects. Within the context of industry performance, this number is significant, demonstrating SBM Offshore‘s leading position in EPCI for the turret market. The Prelude turret is the first concrete example of SBM Offshore’s successful entry into the FLNG turret market, while the Ichthys turret for the client’s condensate FPSO adds to the Company’s gas track record.

- From an award perspective, the Company secured the contract for the Johan Castberg turret mooring system, following completion of the FEED to the client’s satisfaction.

Fritz H. Eilertsen − Statoil ASA

Company representative (CR) − Turret Mooring System − Johan Castberg project

’SBM Offshore’s competence and experience base as a leading supplier of Turret Mooring Systems have been important contributions in the work of maturing the Johan Castberg project towards the Final Investment Decision (FID) end of 2017. Through this work, Statoil has learned to know SBM Offshore as a professional actor, and established a solid basis for further cooperation in the upcoming project phases.’

Future

The Company continues to invest in its capacity in the turnkey division in order to be ready for when the market picks up further. In the meantime, the Company aims to be the preferred contractor for FEEDs, an area that is active, while clients assess the viability of projects.