1.6Position within the Value Chain

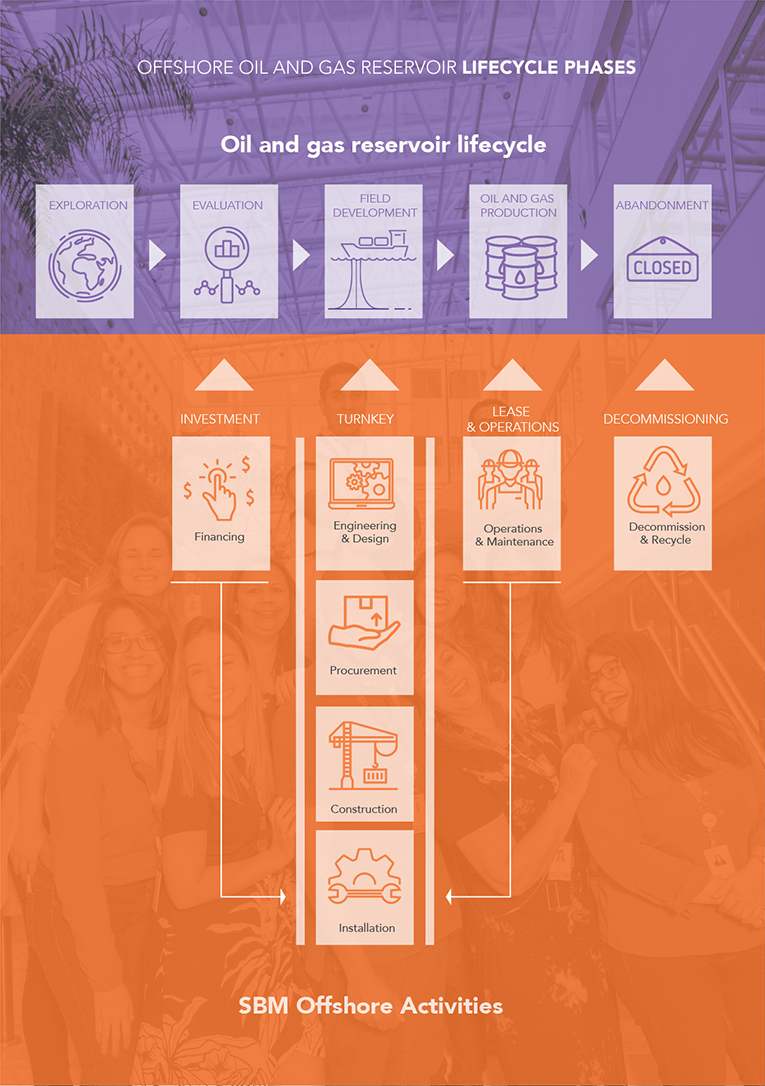

SBM Offshore is mostly active in the offshore oil and gas industry and provides a broad range of products and services to its clients with the goal to produce oil and gas from underwater reservoirs containing hydrocarbons. The illustration outlines the lifecycle phases of the industry at large and SBM Offshore’s activities within this cycle.

The Company’s clients usually control the complete value chain from the initial exploration phase to the physical distribution of hydrocarbon-based products. SBM Offshore’s added value in their value chain primarily relates to field development activities. The Company is to a much lesser extent involved in the transportation of crude oil – its CALM Buoys transfer crude oil from VLCC carriers to and from storage on shore.

SBM Offshore’s Value Chain

SBM Offshore’s Value Chain is reflected in the lifecycle circle of the full service of producing oil and gas offshore for its clients. There are different elements related to this service that require different skill sets and have a different value proposition.

Financing

SBM Offshore constructs and supplies floating production facilities for lease and operate activities as well as direct sales to clients. When sold to a third party, a sales margin is generated and ownership is transferred to the client. In the case of a lease and operate contract, the facility is usually sold to Asset specific companies − in which SBM Offshore retains a stake. These asset specific companies then charter and operate the asset (FPSO or FPU) for the client. In both cases, the construction activities create value through manufacturing and are described hereafter.

Engineering and Design

SBM Offshore has the in-house capability for conceptual studies, basic design and detailed design. This expertise is required to engineer the facilities to meet the specific requirements of the field development. SBM Offshore invests in product and technology development to maintain the required technology innovation and expertise to meet its clients’ requirements and increase its competitive advantage.

Procurement

SBM Offshore’s supply chain represents a substantial part of the total costs to construct an FPSO. Controlling the supply of bulk, equipment and services, in a cost-effective and timely manner, to support the construction phase is essential to delivering the facility on schedule and on budget.

Construction

SBM Offshore outsources most construction activities to refurbish and convert a hull into an FPSO or build a new hull (MPF) as well as fabricate and integrate the process modules. To meet local content requirements in its core markets, the Company invested in two Joint Venture yards to undertake these two main activities. Following mechanical completion, an FPSO is then commissioned by SBM Offshore before moving offshore for installation and start-up of production operations.

Installation

Installation of the floating facilities is done with specialized installation vessels and requires specific engineering expertise and project management skills. SBM Offshore is co-owner of two installation vessels that provide the expertise to install its fleet of FPSOs offshore, as well as performing other offshore construction works for third parties. Access to these vessels allows SBM Offshore to control the risks associated to cost fluctuations over a period of several years from contract award. These vessels also work for third parties to optimize return on investment.

Operations & Maintenance

The Assets Specific companies, fully owned by SBM Offshore or Co-owned with partners, which are leasing offshore facilities to clients, are mostly operating those facilities as well. This activity creates value for clients as the uptime performance of the facility directly impacts the amount of hydrocarbons produced. In most contracts, these Assets Specific Companies are compensated for providing the production facilities against a fixed dayrate complemented with an operating fee. Income is independent of oil price fluctuations. Most contracts include a bonus/penalty reward related to uptime performance of the different systems as well as penalties related to GHG emission levels.

The facility processes the well fluids into stabilized crude oil for temporary storage on board, which is then transferred to a shuttle tanker to export it from the field. Oil and gas enhanced recovery systems are used to maintain production levels. To do this, secondary recovery systems for gas injection, water injection and gas lift systems are installed on the production facility. SBM Offshore’s Generation 3 FPSO design for deep water includes CO2 removal from gas stream and reinjection into the well offshore.

Operating and maintaining offshore oil and gas production facilities requires proven operational expertise and management systems, which SBM Offshore has developed over a cumulative 300 contract years of operations.

Decommissioning & Recycling

At the end of the lifecycle – either due to the duration of the contract coming to an end or depletion of the client’s field – the facilities are decommissioned and recycled. As the leased FPSOs are under SBM Offshore’s full or co-ownership, the Company applies the Hong Kong Convention rules to green recycle its FPSOs.

Variations in the Value Chain

Modifications & equipment supply

Some of SBM Offshore’s Product Lines operate in a slightly different value chain. Although the majority of the Company’s contracts are based on the lease and operate business model, it also supplies FPSOs and specific FPSO equipment, such as Turret Mooring Systems, on a turnkey supply basis.

Part of the operating activities are devoted to the modification of existing floating offshore installations, to enable the Company’s clients to extend the production life of the facility, to tie-in smaller fields nearby or to upgrade with new technology.

Gas and Renewables

The Company’s Gas & Renewables Product Line emphasizes SBM Offshore’s strategic intention to position the Company in this growing market sector, with focus on:

- Floating renewable energy systems (wind, wave)

- Floating cryogenic gas systems (FLNG, FLPG)